How to relocate?

Any change in purchasing or production - offshoring and reshoring - leads to the same risks:

Any change in purchasing or production - offshoring and reshoring - leads to the same risks:

supply disruptions,

cost increases,

fluctuating quality,

long lead times, poor flexibility.

Based on the experience of its founders, innotelos created a reshoring methodology to reduce vulnerabilities:

20 questions to analyze the current situation,

20 reshoring actions to increase resilience.

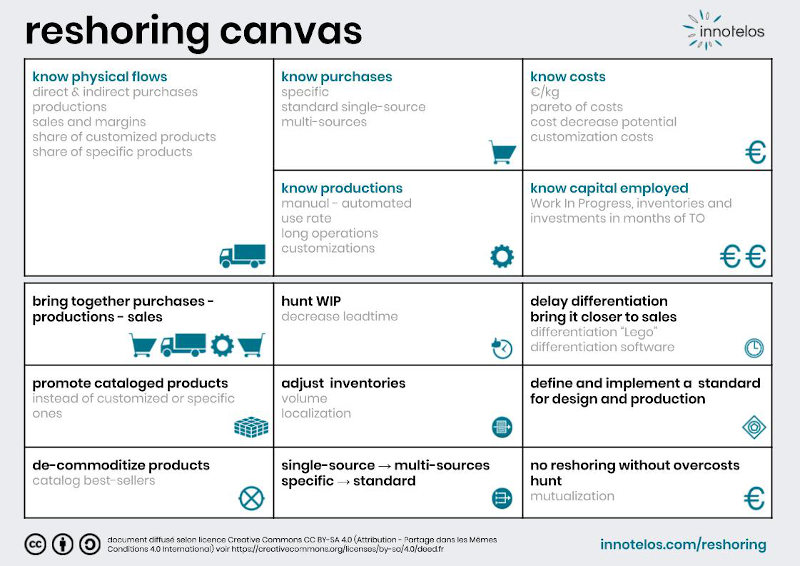

The Reshoring Canvas summarizes our methodology.

The 2 videos below illustrate with examples our relocation methodology and the Reshoring Canvas.

Feasibility of reshoring

Part 1 of the relocation methodology: analysis

which diagnosis should be made before reshoring?

what are the points of attention?

how to choose what should be relocated first?

Set up a relocation project

Part 2 of the reshoring methodology: decisions for action

what possibilities of relocation?

how to finance reshoring?

which gains? which lead times? which risks?

Consulting & training

Various formulas to support your industrial relocations.

|

"3 hours for" distance training |

1/2 day online 270 € per person contact us |

|

pre-study of relocation feasibility |

1/2 day |

|

relocation diagnosis |

1 day |

|

relocation + cost reduction diagnosis |

2 days online / on site 2,200 € contact us |

|

support in relocation, industrialization, cost reduction |

online / on site get a quote contact us |

|

tailor-made training |

online / on site get a quote contact us |

On site interventions are subject to health & safety regulations and constraints. We are able to provice all or part of our services remotely.

Our experience in international projects is a guarantee of similar efficiency on line and on site.

Reshoring? Relocation?

Contact us!

|

|

|

Crédits

- Text, videos and Reshoring Canvas are authored by Anne Munchenbach et Didier Lebouc (innotelos).

- Reshoring Canevas, freely inspired by Strategyzer canvas, is licensed under Creative Commons Licence Attribution - Share Alikes 4.0 International (CC BY-SA 4.0).

![]()